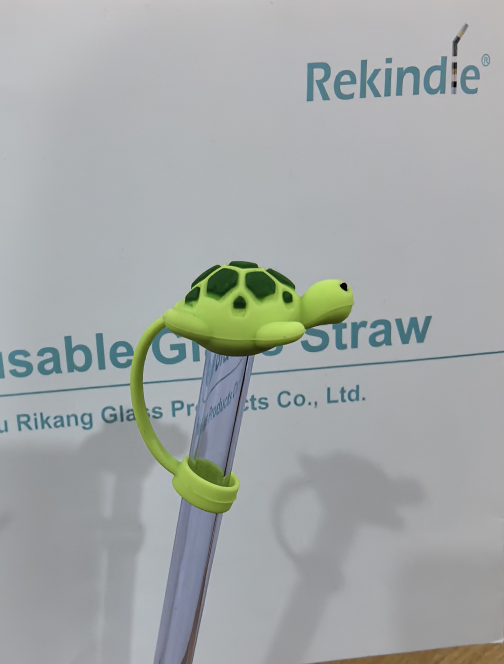

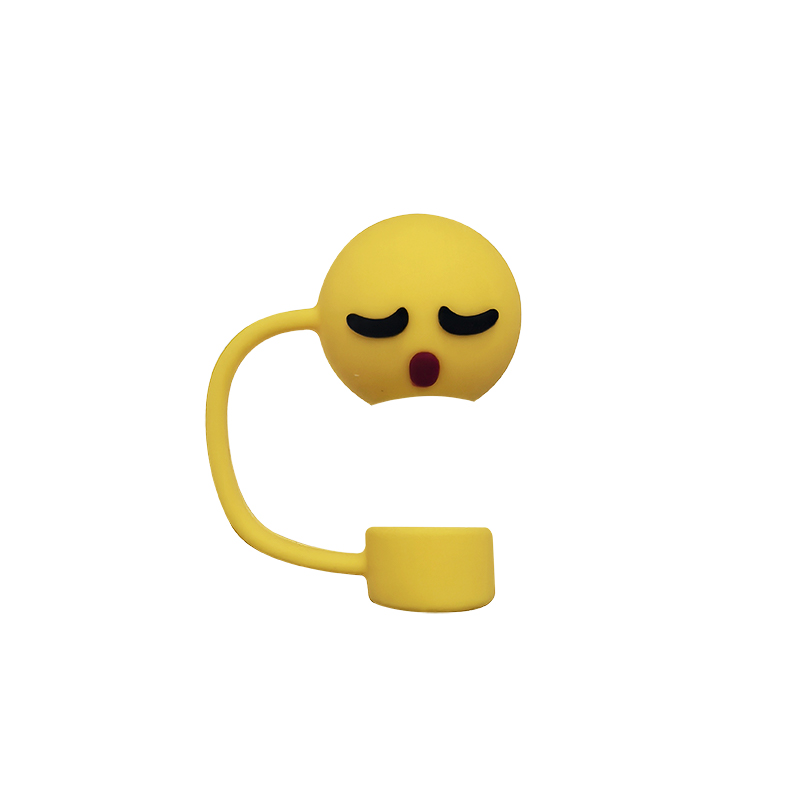

Rekindle Straw – Global Leading Large-scale Straw Topper Factories, Focused on Efficient Production and Quality.

As an industry pioneer since 2008, Rekindle Straw has established itself as a trusted large-scale straw topper manufacturer in the international market, supported by two modern factories and two sales companies with a global footprint. Headquartered in Danyang, Jiangsu Province, China, we integrate R&D, production, and marketing capabilities, leveraging advanced equipment and mature processes to achieve large-scale production and global delivery of straw toppers. Whether you need bulk procurement of standard products or customized mass production, we meet the diverse needs of brand owners, distributors, and corporate clients with high efficiency, strict quality control, and international-standard services, setting a dual benchmark for industry capacity and quality.

Get A Quote